Foil

-

Foil

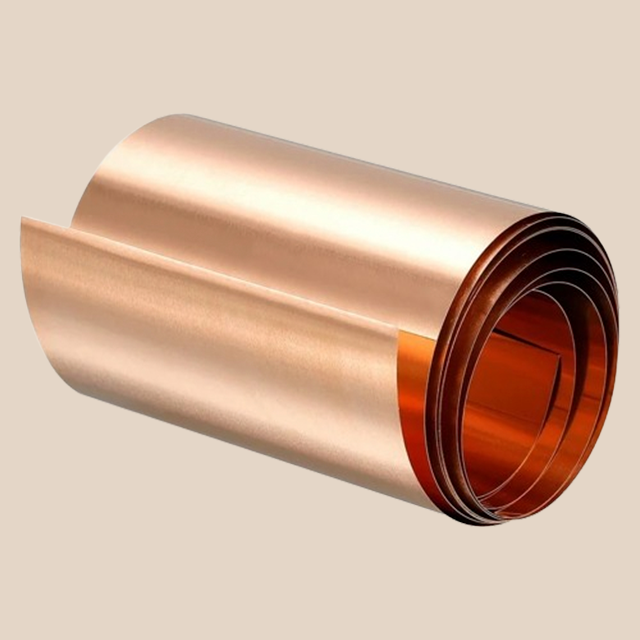

Copper Foil

Copper foil is highly conductive, making it valuable in electronics for creating circuits and electromagnetic shielding. It's also used in stained glass work and various decorative arts where it's adhered to surfaces to add a metallic sheen. Additionally, it finds applications in batteries, roofing, and even in certain medical devices.

It's typically produced through a rolling process, which can result in different thicknesses depending on the intended use.

Phospour Bronze Foil

Phosphor bronze foil is commonly used in electrical and electronic applications due to its excellent conductivity and spring-like properties. It's often employed in electrical contacts, connectors, switches, and other components where a combination of electrical conductivity and mechanical resilience is required.

In addition to its electrical applications, phosphor bronze foil is also utilized in various industrial applications, including springs, bearings, bushings, and corrosion-resistant components in marine environments.

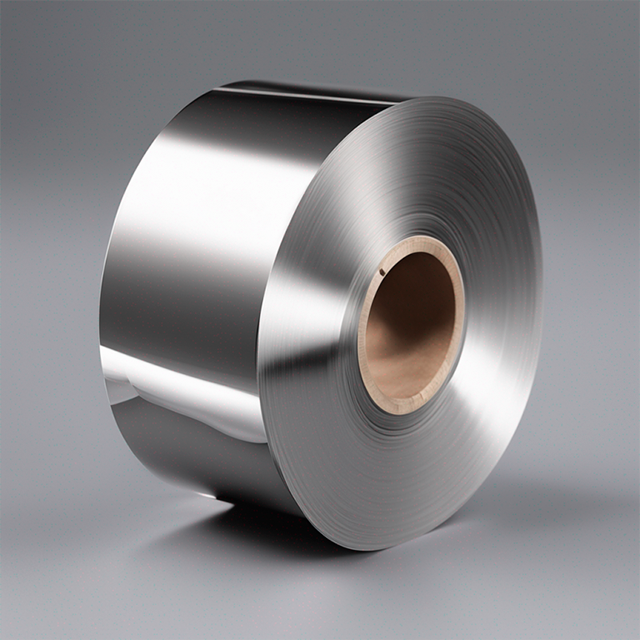

Nickel Foil

Nickel foil is a thin sheet of nickel, a metallic element known for its corrosion resistance, high electrical conductivity, and strength. Nickel foil is produced through a rolling process, which can produce various thicknesses depending on the application.

Nickel foil finds applications in a wide range of industries, including electronics, aerospace, automotive, and energy.

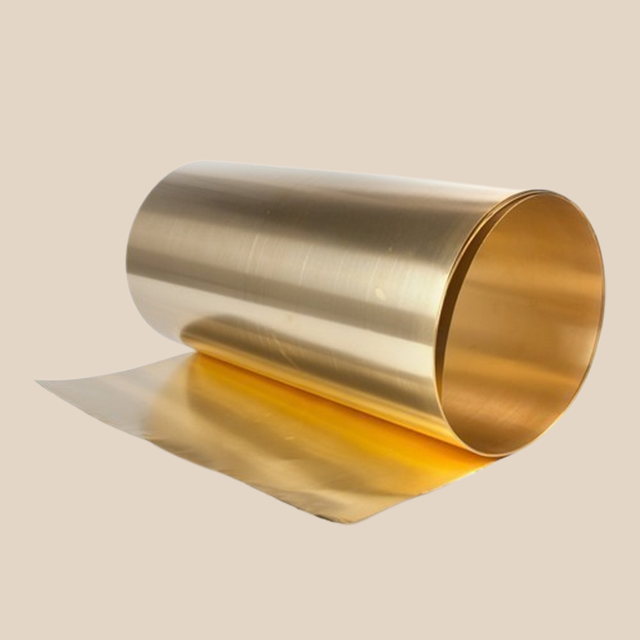

Brass Foil

Brass foil is a thin sheet of brass, an alloy primarily composed of copper and zinc, with varying proportions depending on the desired properties. It shares characteristics with both copper and zinc, offering a blend of their respective properties.

Brass foil offers a balance of aesthetic appeal, malleability, corrosion resistance, and conductivity, making it a versatile material for a wide range of applications in both decorative and functional contexts.